Global Optical Sorter Market Growth to Reach $5.49 Billion by 2030, Driven by Automation and Quality Standards

Global Optical Sorter Market Poised for Significant Growth, Projected to Reach $5.49 Billion by 2030

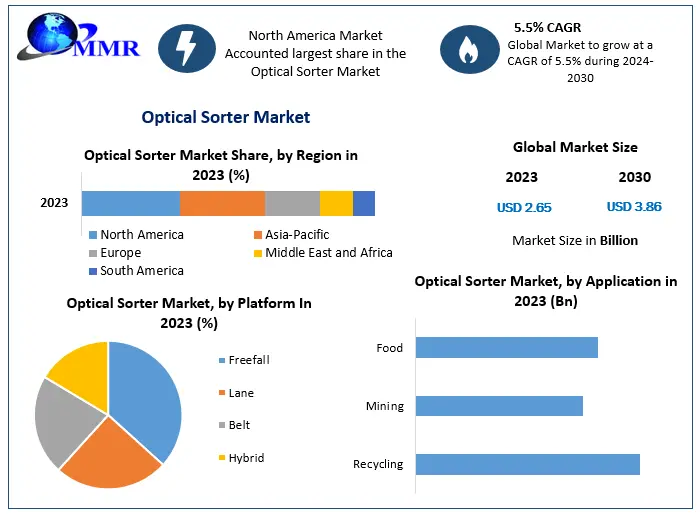

The Global Optical Sorter Market Growth is on an impressive growth trajectory, with projections indicating an increase from $3.42 billion in 2025 to approximately $5.49 billion by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 9.93% during the forecast period. This surge is primarily driven by the escalating demand for automation across various industries, heightened emphasis on product quality and safety, and stringent regulatory standards.

To get the sample please click here: https://www.maximizemarketresearch.com/request-sample/2088/

Market Definition and Estimation

Optical sorters, also known as digital sorters, are automated systems designed to sort solid products based on parameters such as color, size, shape, structural properties, and chemical composition. These systems are extensively utilized across multiple industries—including food processing, recycling, and mining—to enhance product quality, ensure safety, and optimize operational efficiency. The market's estimated growth underscores the escalating adoption of optical sorting technologies to meet industry-specific requirements and regulatory standards.

Market Growth Drivers and Opportunities

Several pivotal factors are driving the expansion of the optical sorter market:

Increasing Automation Needs – Industries are increasingly adopting automation to boost productivity and reduce operational costs. Optical sorters play a crucial role in automating sorting processes, thereby minimizing human error and enhancing efficiency.

Demand for High-Quality Products – Consumers' growing emphasis on product quality and safety has led manufacturers to implement advanced sorting technologies. Optical sorters ensure that only products meeting stringent quality standards reach the market.

Stringent Regulatory Standards – Governments worldwide are enforcing rigorous regulations concerning food safety and waste management. Optical sorters assist companies in complying with these standards by effectively removing defective or contaminated products.

Technological Advancements – Continuous innovations in sensor technology and intelligent software have enhanced the accuracy and efficiency of optical sorters, making them more accessible and appealing to various industries.

Growth in Recycling and Waste Management – The increasing focus on sustainability has amplified the demand for efficient recycling processes. Optical sorters are instrumental in accurately separating recyclable materials, thereby supporting environmental conservation efforts.

Segmentation Analysis

The optical sorter market is segmented based on type, platform, application, and region.

By Type

- Cameras – These are widely used due to their ability to detect minute defects in products, making them essential in food sorting applications such as fruits, vegetables, and nuts.

- Lasers – Utilized for detecting subtle differences in product composition, lasers are effective in identifying foreign materials in processing lines.

- NIR (Near-Infrared) Sorters – These sorters are adept at distinguishing materials based on their chemical composition, making them invaluable in recycling applications.

- Hyperspectral Cameras & Combined Sorters – Combining multiple sensing technologies, these sorters offer enhanced accuracy and are gaining traction in various applications.

By Platform

- Belt – Ideal for high-capacity operations, belt sorters provide a continuous flow, making them suitable for bulk product sorting.

- Lane – These sorters are designed for precise sorting of items in individual lanes, commonly used in applications requiring high accuracy.

- Hybrid – Combining features of both belt and lane platforms, hybrid sorters offer flexibility and efficiency in sorting processes.

- Freefall – Utilizing gravity, freefall sorters are effective for sorting small and lightweight products, often used in food processing.

By Application

- Food – The largest application segment, optical sorters in the food industry ensure the removal of defective or contaminated products, enhancing food safety and quality.

- Recycling – In the recycling sector, optical sorters facilitate the efficient separation of recyclable materials, contributing to environmental sustainability.

- Mining – Optical sorters assist in the mining industry by separating valuable minerals from ores, improving the efficiency of extraction processes.

Country-Level Analysis

United States

The United States represents a significant share of the optical sorter market, driven by advanced technological infrastructure and a strong emphasis on automation across industries. The country's stringent food safety regulations and robust recycling initiatives have further propelled the adoption of optical sorting technologies. The presence of key market players and continuous investments in research and development contribute to the market's growth in this region.

Germany

Germany, known for its engineering excellence, has been a pioneer in adopting advanced manufacturing technologies, including optical sorters. The country's strong industrial base, particularly in the food processing and recycling sectors, has led to a substantial demand for optical sorting systems. Government initiatives promoting automation and sustainability have further accelerated market growth.

Competitive Analysis

The optical sorter market is characterized by intense competition, with several key players striving to enhance their market position through innovation, strategic partnerships, and mergers and acquisitions. Notable companies in the market include:

- TOMRA Systems ASA – A global leader in sensor-based sorting solutions, TOMRA offers a wide range of optical sorters catering to various industries, including food, recycling, and mining.

- Bühler Group – Known for its advanced optical sorting technologies, Bühler serves the food processing industry with innovative solutions ensuring product quality and safety.

- Key Technology, Inc. (Duravant LLC) – Specializing in digital sorting, conveying, and process automation, Key Technology provides optical sorters that enhance efficiency in food processing operations.

- Hefei Meyer Optoelectronic Technology, Inc. – A prominent player in the Chinese market, Meyer Optoelectronic offers a diverse portfolio of optical sorting equipment, catering to food and industrial applications.

- Sesotec GmbH – Focusing on metal detection and optical sorting, Sesotec provides solutions that ensure product purity and compliance with industry standards.

To learn more about the market analysis, read the Summary of the Research Report: https://www.maximizemarketresearch.com/market-report/optical-sorter-market/2088/

Conclusion

The global optical sorter market is poised for substantial growth, driven by the increasing demand for automation, stringent quality standards, and technological advancements. With significant contributions from key industries such as food processing, recycling, and mining, the adoption of optical sorting technology is expected to expand across various regions.

As companies continue to innovate and integrate cutting-edge sorting solutions, the market is set to experience transformative developments, ensuring enhanced product quality, operational efficiency, and sustainability.

Explore additional related reports for more insights and information:

Electric Forklift Market https://www.maximizemarketresearch.com/market-report/electric-forklift-market/198700/

Global Power Management IC Market https://www.maximizemarketresearch.com/market-report/global-power-management-ic-market/65901/

Mini LED Market https://www.maximizemarketresearch.com/market-report/global-mini-led-market/113825/

Comments

Post a Comment